Food grade flexible impeller pump

Food grade flexible impeller pumps, also known as flexible impeller pumps, provide an effective solution for most marine and industrial pumps.

Advantages of Food Grade Flexible Impeller Pumps

1. The main advantage is its excellent self-priming ability. During the bending and recovery process, the rubber blades form a vacuum (negative pressure) in the cavity, sucking the liquid into the pump body. The suction range of the flexible impeller pump can reach 5 meters, so the pump body does not need to be placed below the liquid surface, so it is widely used in deck washing, engine cooling systems or manual filling.

2. Another advantage of the chemical flexible impeller pump is that it can transport liquids containing large particles without being blocked or damaged, which greatly reduces the need for filtering the inhaled liquid.

Smooth and gentle, completely pulsation-free

1. For products that are sensitive to extraction, the flexible impeller pump’s suction process is very smooth and gentle, and will never whip or damage the product, even if it is as delicate as high-fat cream.

2. Even berry-sized media can pass through the pump smoothly, and the flexible impeller pump ensures completely pulsation-free operation.

Can be used as a dosing pump

By adjusting the speed of the pump, it can also be used as a dosing pump.

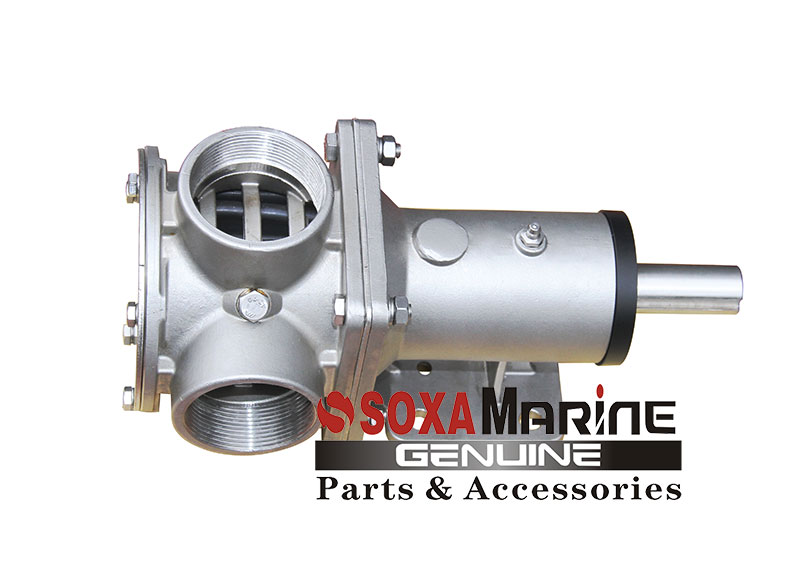

Provide two different materials of rubber impeller and food grade rubber impeller

For most of Songxia Marine’s flexible impeller pumps, we can provide two different types of rubber impellers.

1. Standard, high-life neoprene impellers are suitable for most seawater or freshwater liquids

2. Oil-resistant nitrile rubber impellers are more suitable for oil or oil-water mixed liquids.

For some food industry applications, we have food-grade rubber impellers to choose from.

A characteristic of food grade flexible impeller pump is that it cannot run dry for more than 30 seconds, because in the absence of liquid, the impeller and seals that rely on liquid lubrication will be damaged quickly. For all standard products, consumables are easy to replace, and we can provide corresponding maintenance kits.

The following is the product parameter table we developed:

Power reference value

| Name | Model | Material | Outlet | Shaft(mm) | Size(mm) | Weight(kg) | Impeller | Flow(1400RPM) | Motor Power |

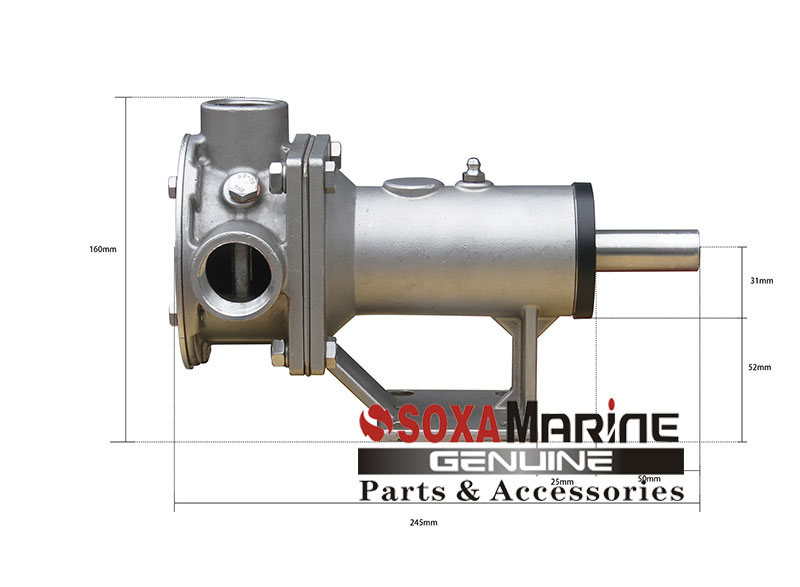

| Impeller pump | SOXA-1 | 316 Stainless steel | 1" | 17 | 120*120*230 | 4.5 | 17FI021 | 82L/Min | 0.5kw |

| SOXA-2 | 1-1/4" | 20 | 130*150*230 | 4.6 | 17FI028 | 120L/Min | 0.75kw | ||

| SOXA-3 | 1-3/4" | 25 | 160*160*260 | 6.3 | 17FI031 | 160L/Min | 1.1kw | ||

| SOXA-4 | 2-1/4" | 25 | 170*170*300 | 7.5 | 17FI039 | 286L/Min | 2.2kw |